SKE's non-intrusive mounted ultrasonic level sensors address liquid ammonia's unique challenges through non-contact, high-precision monitoring and effortless installation – delivering a revolutionary safety solution for liquid ammonia storage / transport operations.

In the hot summer of June, under the tropical sunshine of Hainan, a well-known company dedicated to biotechnology research and development and production is operating efficiently and thriving.

In the high temperature and high humidity island climate, the liquid level management of the liquid ammonia storage tank area is directly related to the

production efficiency and operation safety of the biotechnology company as a key link in its production chain. In response to the measurement needs

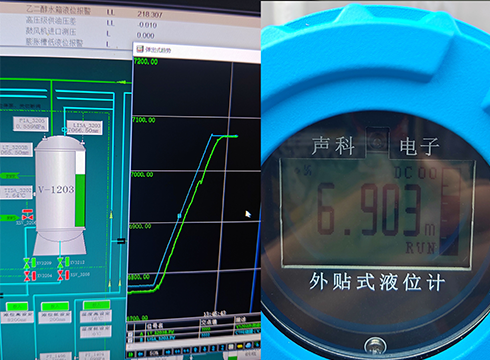

of liquid ammonia, a special medium, the non-invasive ultrasonic level gauge of Shengke Electronics has successfully provided a new industry solution

for the safety of liquid ammonia storage and transportation with its excellent characteristics of non-contact, high precision and easy installation.

It has been more than a year since our company's non-invasive ultrasonic level gauge was deployed in a biotechnology company in Hainan from the early

stage of all-round communication and understanding of the actual working conditions of the customer project.

In the following article, we will share this successful application case to explain how Shengke Electronics provides customers with efficient and reliable high-risk medium level measurement solutions.

The severe challenges of liquid ammonia storage tank area monitoring.

Liquid ammonia is a highly corrosive, low-temperature, and volatile hazardous medium, placing extremely high demands on tank level measurement equipment.

This company's core production process relies on large quantities of liquid ammonia, making the safety of its storage tanks crucial to its development.

SKE's solution: SKE's independently developed externally mounted ultrasonic level gauge utilizes advanced sonar ranging technology. Through micro-vibration analysis and a high-speed signal processing chip, it overcomes the limitations of container wall thickness and achieves true non-contact liquid level measurement.

This device requires no holes in the tank; simply attaching the dual sensor probes to the tank's exterior allows for precise measurement of liquid ammonia levels. Its core advantages include:

1. Absolute safety and leak prevention

2. Intelligent penetrating and precise monitoring

3. Safe operation in high-temperature and high-humidity environments

4. Maintenance-free.

Reduced operation and maintenance burden: maintenance frequency has been reduced by 90%, reducing the number of high-risk operations and ensuring personnel safety.

Data Empowerment: Liquid level data is integrated into the DCS system in real time, enabling dynamic management of liquid ammonia inventory and more accurate purchasing decisions.

In the future, Shengke Electronics will continue to focus on the research and development and innovation of external ultrasonic measurement technology, launch more intelligent measurement equipment to meet the needs of different industries, and provide global customers with safer, smarter, more accurate and efficient industrial ranging solutions with innovative sensor technology as the core, safeguarding the inherent safety of process industries!

CN

CN