Show more

-

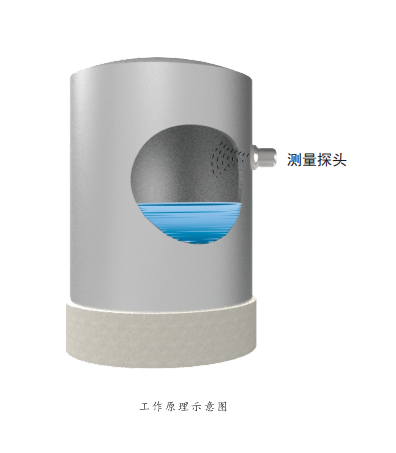

Non-invasive ultrasonic level gauge for Chlorine storage tank

Level and point level measurement in Chlorine storage tanks

-

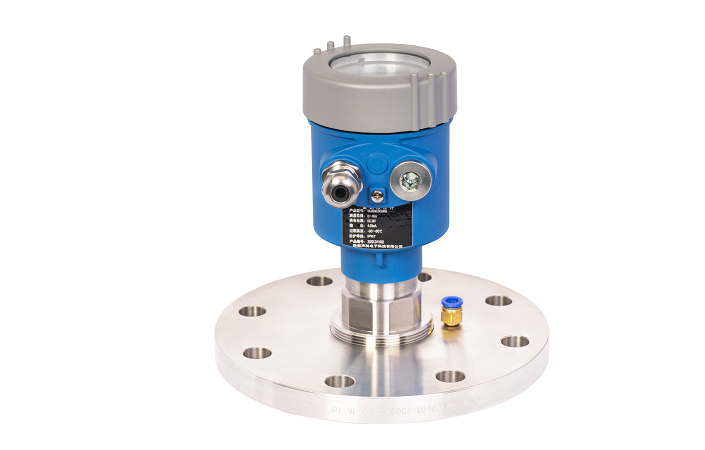

Radar Level Transmitter in Storage Tank

Level and point level measurement in small storage and buffer containers

Show more

-

Mo source storage tank

Show more

-

Liquid waste buffer tank

Level and point level measurement in buffer tanks for liquid waste

Show more

-

Storage Tanks for Liquids

Level and point level measurement in storage tanks for liquids

Show more

-

Storage tanks for pure water, milk, juice

Level measurement in edible liquid tanks such as purified water

Show more

-

Storage tank for beer bottling

Level measurement in storage containers for beer filling

Show more

-

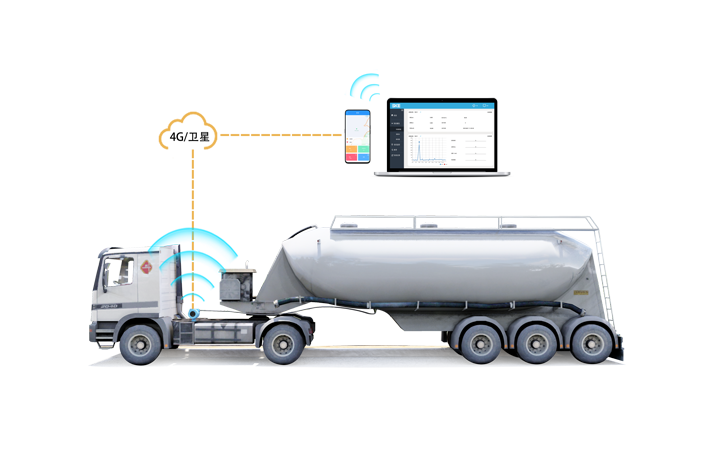

Non-invasive ultrasonic level sensor for spherical LPG tank

LPG tank level measurement

Show more

-

Level Measurement for Urea reactor

Level measurement in a urea reactor

Show more

-

Ultrasonic level Tank level sensor for chemical solvents tank

Level measurement in chemical solvents tank

Show more

-

Storage tanks level sensor for toxic liquids tank

Level measurement in toxic liquid storage tank

Show more

-

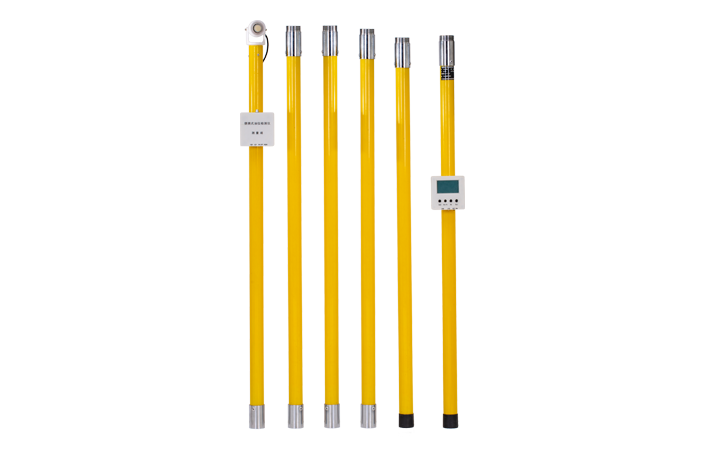

Propane Bullet Tanks

Level measurement in propane bullet spherical tank, LPG spherical bullet Tanks

Show more

-

Fixed roof storage tanks

Measuring liquid levels in petroleum and liquid petroleum product of storage tanks

Show more

-

Acid slurry tanks

Level monitoring in acid residue tanks

Show more

-

Anhydrous ammonia storage tank

Level measurement and point level detection in the anhydrous ammonia storage tank

Show more

CN

CN