Show more

-

Non-invasive ultrasonic level gauge for Chlorine storage tank

Level and point level measurement in Chlorine storage tanks

-

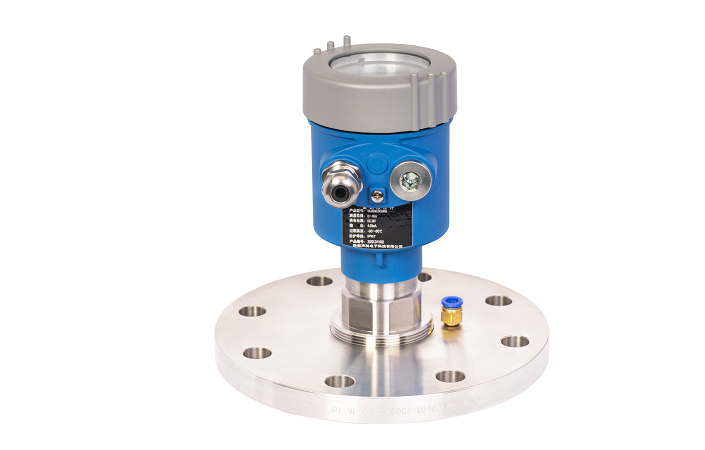

Radar Level Transmitter in Storage Tank

Level and point level measurement in small storage and buffer containers

Show more

-

Mo source storage tank

Show more

-

Liquid waste buffer tank

Level and point level measurement in buffer tanks for liquid waste

Show more

-

Storage Tanks for Liquids

Level and point level measurement in storage tanks for liquids

Show more

-

Storage tanks for pure water, milk, juice

Level measurement in edible liquid tanks such as purified water

Show more

-

Storage tank for beer bottling

Level measurement in storage containers for beer filling

Show more

-

Radar Level Transmitter for Pumping station

Water Level measurement & control in a pumping station

Show more

-

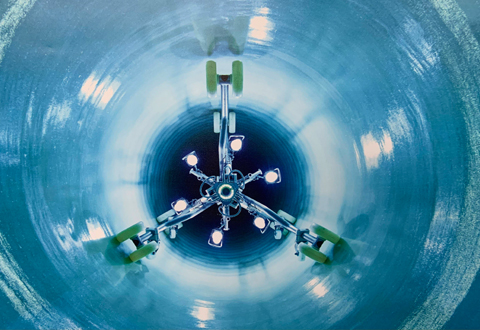

Gullies

Detecting deposits in gullies with radar water level measurement

Show more

-

Process water tank

Level measurement in operating water tank

Show more

-

Sewer network

Measuring water levels in sewer networks

Show more

-

Water storage tanks

Level measurement in storage tanks

Show more

-

Level measurement in river

Water level monitoring in open channels

Show more

-

Non-invasive ultrasonic level sensor for spherical LPG tank

LPG tank level measurement

Show more

-

Level Measurement for Urea reactor

Level measurement in a urea reactor

Show more

-

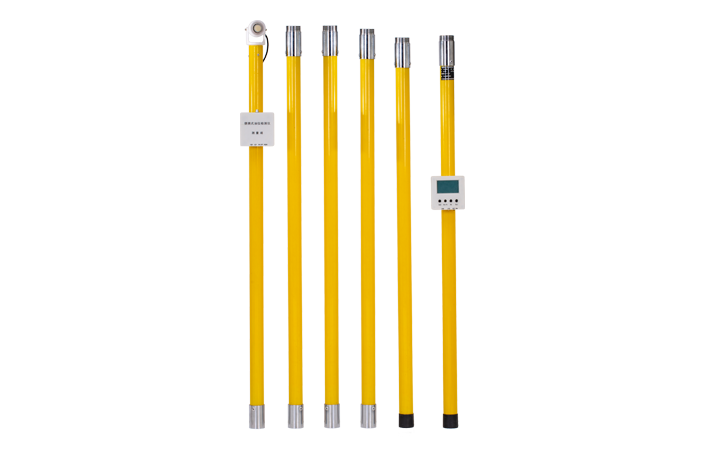

Ultrasonic level Tank level sensor for chemical solvents tank

Level measurement in chemical solvents tank

Show more

-

Storage tanks level sensor for toxic liquids tank

Level measurement in toxic liquid storage tank

Show more

-

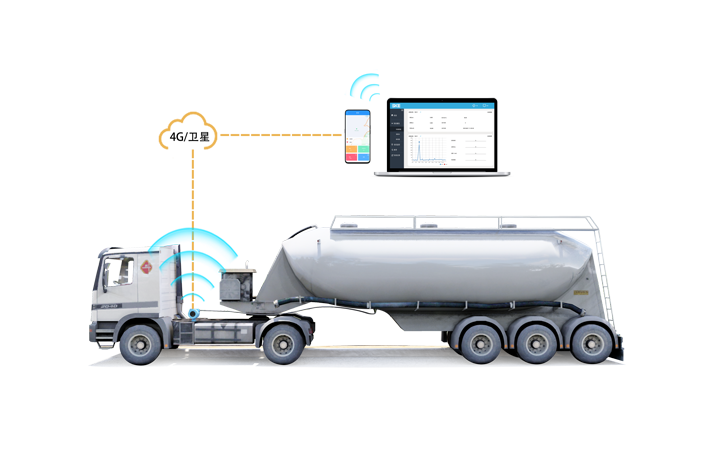

Transport container for liquids (metal)

Level measurement of liquids in transport containers

Show more

-

Propane Bullet Tanks

Level measurement in propane bullet spherical tank, LPG spherical bullet Tanks

Show more

-

Sump Level Sensor

Level control in sump, Sump level sensor measurement transmitter

Show more

CN

CN